Fiberglass Reinforced Plastic (FRP) sheets are widely used across various industries due to their exceptional durability, lightweight properties, and corrosion resistance. These sheets are made from a composite material, combining fiberglass and a resin matrix, providing strength and versatility. However, to enhance their performance and aesthetic appeal, gel coat is often applied to the surface of FRP sheets.

In this article, we’ll dive into what gel coat sheets are, the role of gel coat in FRP sheets, and how these components contribute to the overall durability and aesthetic appeal of fiberglass gel coat sheets.

What is Gel Coat in FRP Sheets?

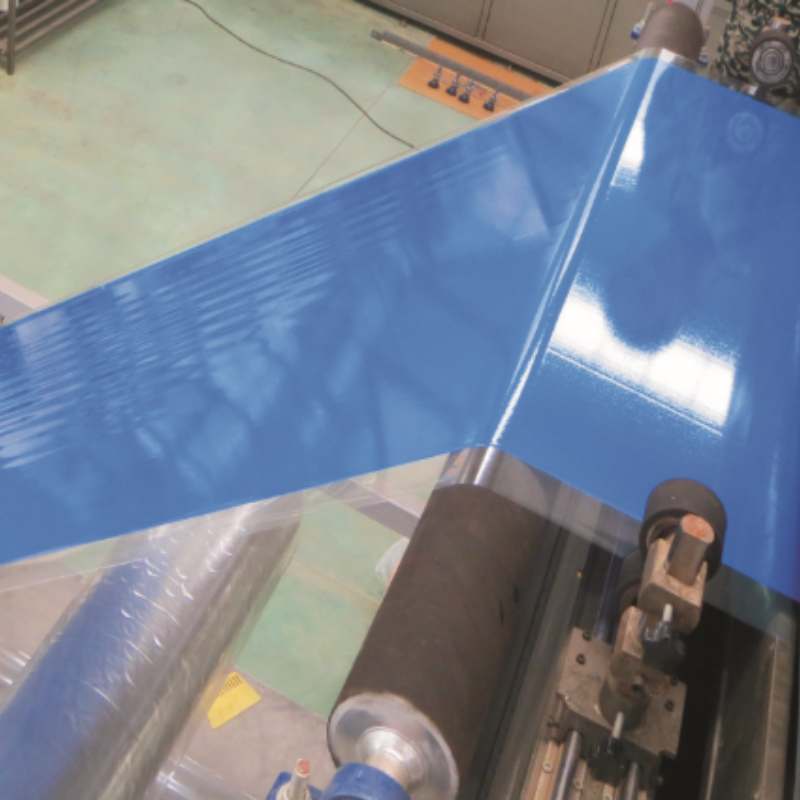

Gel coat is a specialized coating applied to the surface of FRP sheets. It is typically made from polyester or vinyl ester resins and acts as a protective layer, offering both functional and aesthetic benefits. The gel coat is typically applied during the manufacturing process of fiberglass sheets, forming the outer layer that provides a smooth, glossy finish.

Gel coat plays a crucial role in protecting the FRP sheet from environmental factors, such as UV rays, moisture, and chemicals. It also improves the appearance of the fiberglass gel coat sheet, making it more visually appealing while maintaining its structural integrity.

Why is Gel Coat Important in FRP Sheets?

Enhanced Durability and Protection

The primary role of gel coat in FRP sheets is to enhance their durability by providing an additional protective layer. Gel coat sheets are resistant to environmental factors such as UV radiation, chemicals, and moisture, which can degrade the underlying fiberglass. This protective layer prevents the FRP sheet from fading, cracking, or becoming brittle, ensuring its longevity and performance over time.

Improved Aesthetic Appeal

Gel coat enhances the aesthetic qualities of FRP sheets. By applying a gel coat finish, fiberglass gel coat sheets can achieve a glossy, smooth, and aesthetically pleasing appearance. This is particularly important in industries where the visual appeal of the product is crucial, such as architectural applications, boat building, or automotive components.

UV Protection

One of the key features of gel coat is its ability to protect FRP sheets from harmful UV rays. UV radiation can cause fiberglass to degrade over time, leading to fading, discoloration, and loss of strength. The gel coat acts as a barrier, absorbing the UV rays and preventing them from penetrating the fiberglass material, thereby preserving the appearance and integrity of the FRP sheet.

Chemical and Corrosion Resistance

Gel coat provides an additional layer of chemical resistance, making fiberglass gel coat sheets ideal for use in corrosive environments. FRP sheets with a gel coat are highly resistant to acids, alkalis, and other chemicals, making them suitable for applications in industries such as chemical processing, marine, and food processing, where exposure to harsh substances is common.

Increased Strength

The gel coat layer also contributes to the overall strength of the FRP sheet. While the fiberglass reinforcement provides strength and support, the gel coat layer increases the structural integrity of the sheet by acting as a barrier against impact and abrasion. This is especially important for applications that require durable, long-lasting materials, such as construction, automotive, and industrial equipment.

Applications of FRP Gel Coat Sheets

Marine Industry

Fiberglass gel coat sheets are extensively used in the marine industry to manufacture boats, yachts, and other watercraft. The gel coat provides a glossy finish that improves the visual appeal of the vessel while offering protection against saltwater and UV damage. This helps to preserve the boat’s exterior, ensuring it remains in top condition even when exposed to harsh marine environments.

Construction and Architecture

In the construction and architectural sectors, FRP gel coat sheets are used for wall cladding, roofing, and decorative panels. The gel coat layer helps to enhance the aesthetic appeal of these panels while providing weather resistance and durability, making them perfect for both indoor and outdoor applications.

Automotive and Aerospace Industries

In the automotive and aerospace industries, fiberglass gel coat sheets are used to manufacture body panels, parts, and structural components. The smooth finish provided by the gel coat improves the appearance of the vehicle while protecting the fiberglass structure from wear, tear, and environmental degradation.

Food Processing and Chemical Industries

The chemical and food processing industries also benefit from the use of gel coat sheets in FRP applications. The chemical resistance and corrosion resistance offered by gel coat make fiberglass sheets ideal for use in equipment and containers that come into contact with harsh chemicals or food products.

How to Choose the Right Gel Coat for Your FRP Sheets

When choosing gel coat sheets for your project, it is essential to consider several factors to ensure you select the best option for your needs:

UV Resistance – If the application involves outdoor exposure, selecting a gel coat with excellent UV resistance is crucial to prevent fading and degradation from sunlight.

Chemical Resistance – Depending on the environment, you may require a gel coat that provides additional protection against specific chemicals or acids.

Aesthetic Needs – If appearance is important, you may opt for gel coat sheets that offer a glossy, high-quality finish for a more attractive and polished result.

Thickness and Durability – Depending on the intended application, consider the thickness and durability of the gel coat to ensure it provides the necessary protection for your fiberglass sheet.

Conclusion: The Importance of Gel Coat Sheets in FRP Manufacturing

In conclusion, gel coat sheets play a vital role in the manufacturing of FRP sheets, offering enhanced durability, UV protection, chemical resistance, and aesthetic appeal. The fiberglass gel coat sheet not only ensures the longevity and performance of FRP materials but also adds value in terms of aesthetics and functionality.

If you’re looking for high-quality FRP sheets with superior gel coat finishes, our team at [Your Company Name] can provide custom solutions tailored to your specific needs. Contact us today to learn more about our fiberglass gel coat sheets and how they can benefit your next project.

Keywords: FRP sheet, gel coat sheet, gel coat, fiberglass gel coat sheet, FRP gel coat, fiberglass sheets, FRP gel coat sheets for marine, UV resistant gel coat, fiberglass gel coat for construction.