The FRP continuous lamination process is a highly efficient and reliable method used in the production of fiberglass sheets, which are widely known for their strength, durability, and versatile applications in various industries. By combining fiberglass reinforcement with a resin matrix, this process produces FRP sheets (Fiberglass Reinforced Plastic sheets) that offer exceptional performance in numerous demanding environments.

In this article, we'll explore the FRP continuous lamination process, its benefits, and how it enhances the quality of fiberglass sheets for a wide range of applications.

The Process of Continuous Lamination in FRP Production

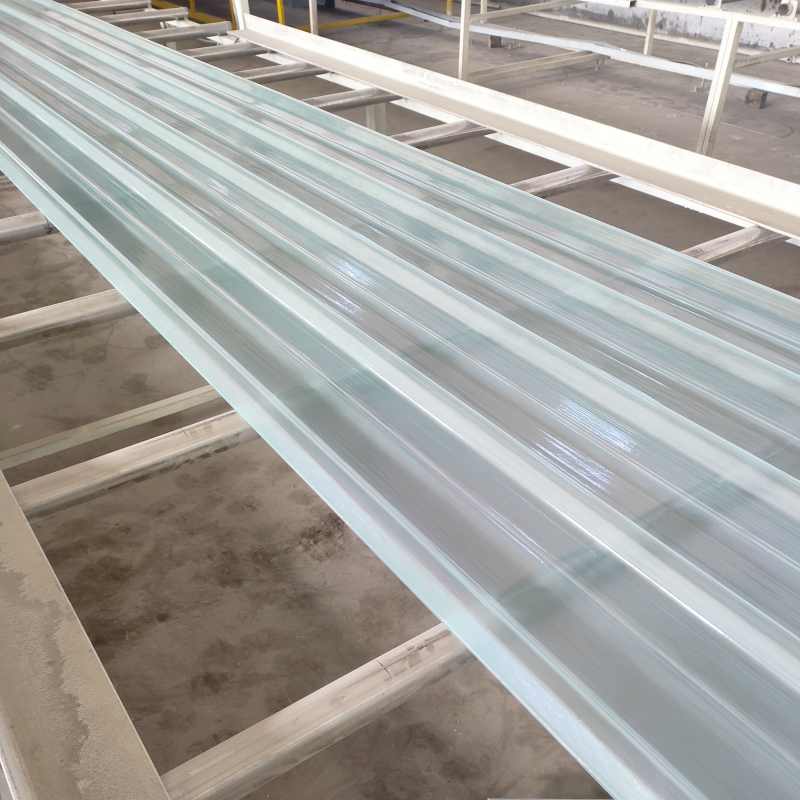

The continuous lamination process for FRP sheets involves a series of automated steps that result in the consistent and uniform formation of fiberglass-reinforced plastic materials. This process allows for the production of long, continuous sheets, making it ideal for applications that require large, uniform sheets of fiberglass for construction, roofing, automotive, and other heavy-duty applications.

Here's a step-by-step look at how the FRP continuous lamination process works:

Resin Impregnation: The process starts with the application of a specific type of resin, typically unsaturated polyester or vinyl ester, which is applied to the fiberglass reinforcement (fiberglass mat or roving). The resin imparts critical characteristics like flexibility, strength, and corrosion resistance.

Fiberglass Layering: The fiberglass reinforcement is laid out in continuous layers. This reinforcement provides the necessary structural strength to the finished FRP sheet. The fibers may be woven, chopped, or aligned in specific orientations to enhance the mechanical properties of the fiberglass sheet.

Continuous Curing: As the resin-impregnated fiberglass passes through a heated curing zone, the resin hardens and bonds with the fibers. The curing process solidifies the material, enhancing the final sheet's strength, stability, and durability.

Cooling and Cutting: After curing, the FRP sheet is cooled down, and the continuous sheet is cut into desired lengths. The final product is then ready for further processing, including molding, cutting, or shaping, depending on the application requirements.

Key Benefits of the FRP Continuous Lamination Process

The FRP continuous lamination process offers several advantages, making it the go-to method for manufacturing fiberglass sheets for diverse industries. Here are some key benefits:

High Strength-to-Weight Ratio: By combining fiberglass reinforcement with resin, FRP sheets produced through continuous lamination are both lightweight and exceptionally strong. This makes them ideal for use in construction, automotive, and aerospace applications.

Customizable Properties: The FRP continuous lamination process allows for customization of the fiberglass sheet's mechanical and thermal properties. By adjusting the type of resin, fiber orientation, and number of layers, manufacturers can tailor the product to meet specific performance needs.

Corrosion Resistance: One of the standout features of fiberglass sheets produced through continuous lamination is their high resistance to corrosion, making them a superior choice for outdoor and industrial applications where traditional materials like metal or wood would degrade over time.

Cost-Effectiveness: The continuous production process is highly efficient, reducing material waste and labor costs. It also allows for the mass production of large volumes of fiberglass sheets, making it a cost-effective solution for high-demand industries.

Enhanced Durability: The lamination process ensures a strong bond between the fiberglass reinforcement and the resin, resulting in fiberglass sheets that are highly durable and long-lasting. This makes them ideal for use in harsh environments, such as chemical plants, coastal buildings, and factories.

Applications of FRP Sheets

FRP sheets produced through the continuous lamination process are used in a wide range of applications due to their excellent mechanical properties, corrosion resistance, and lightweight nature. Here are some common applications:

Roofing: Fiberglass sheets are often used in commercial and residential roofing for their lightweight nature and ability to withstand extreme weather conditions.

Construction: FRP sheets are commonly used in building facades, walls, and partitions, offering an alternative to metal and other materials prone to corrosion.

Automotive: The continuous lamination process is used to produce fiberglass panels in the automotive industry, offering lightweight yet durable options for car bodies and other components.

Water Treatment: Fiberglass reinforced plastic sheets are ideal for use in water treatment facilities, where their corrosion resistance is crucial.

Agriculture: FRP sheets are used in agricultural buildings and greenhouses to ensure protection from harsh weather while providing effective light diffusion.

Why Choose FRP Sheets for Your Project?

FRP sheets made through the continuous lamination process offer many advantages over traditional materials like metal, wood, or concrete. They are highly durable, resistant to corrosion, and versatile, making them an ideal solution for a wide range of applications in various industries. Additionally, their customizable properties allow manufacturers to meet specific performance and design requirements.

Whether you are building a greenhouse, a factory, or designing automotive parts, fiberglass sheets produced through continuous lamination can provide the strength, durability, and flexibility you need.

Conclusion

The FRP continuous lamination process is a cutting-edge technology that produces fiberglass sheets with superior strength, durability, and performance. By combining fiberglass reinforcement with resin, this process results in lightweight, corrosion-resistant sheets that can be tailored to specific needs. From construction to automotive and agriculture, FRP sheets offer an ideal solution for a variety of industries.

If you are looking for high-quality fiberglass sheets for your project, explore the benefits of the FRP continuous lamination process and discover how it can improve your product's performance and longevity.