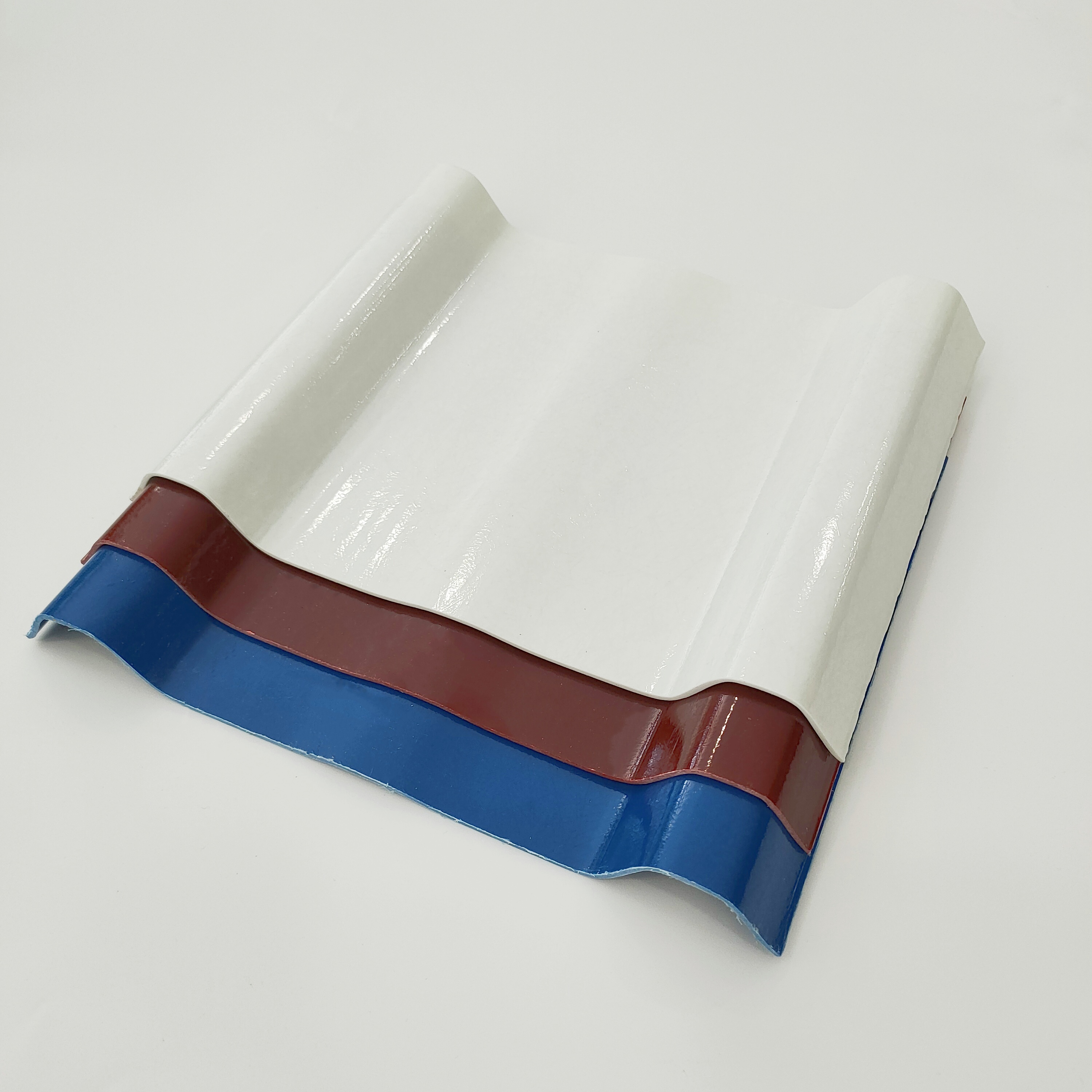

FRP (Fiberglass Reinforced Plastic) anticorrosion roofing sheets are highly versatile and designed to withstand chemically aggressive and harsh environmental conditions. Their durability, lightweight design, and corrosion-resistant properties make them ideal for a variety of applications across industries. Here are some of the key areas where FRP anticorrosion roofing sheets are commonly used:

1. Chemical and Petrochemical Plants

Roofing for factories dealing with hazardous chemicals and gases.

Resistant to corrosion caused by acids, alkalis, and chemical vapors.

2. Agricultural and Livestock Facilities

Greenhouses: Allowing light transmission while resisting humidity, pesticides, and fertilizers.

Livestock Shelters: Protect against ammonia emissions and harsh cleaning chemicals.

3. Power and Energy Facilities

Used in cooling towers, chimneys, and substations to withstand extreme environmental and temperature changes.

Effective against corrosion caused by exposure to industrial byproducts.

4. Wastewater Treatment Plants

Provides durable roofing solutions in highly humid and chemically aggressive environments.

Protects against corrosive gases like hydrogen sulfide and other byproducts.

5. Food Processing and Pharmaceutical Units

Ideal for areas requiring high levels of hygiene.

Resistant to corrosive cleaning agents and maintains durability in varying temperature ranges.

6. Marine and Coastal Buildings

Perfect for shipyards, dock warehouses, and coastal factories where salt-laden air causes rapid corrosion.

Resistant to saltwater and UV radiation for longer service life.

7. Industrial Warehouses and Manufacturing Units

Used for roofing warehouses and factories handling corrosive materials or exposed to harsh environments.

Provides excellent protection with minimal maintenance.

8. Mining and Metallurgy Facilities

Protects against corrosive dust, moisture, and other harsh conditions in mining or smelting operations.

Long-lasting even in challenging environments.

9. Transportation Hubs

Can be used in logistics warehouses, loading docks, and parking structures where exposure to pollutants and weather elements is high.

10. Public and Institutional Buildings

Suitable for facilities like water storage tanks, laboratories, and sewage treatment units requiring anti-corrosion properties.

Why Choose FRP Anticorrosion Roofing Sheets?

Chemical Resistance: Withstands exposure to acids, alkalis, and salts.

Durability: Designed for long-term use in challenging conditions.

Cost-Effective: Minimal maintenance required over the lifespan.

Lightweight and Easy to Install: Reduces structural load and installation time.

Customizable: Available in various sizes, colors, and finishes to meet specific requirements.

FRP anticorrosion roofing sheets are indispensable in environments that demand durability, corrosion resistance, and cost-efficiency. Their adaptability makes them the roofing material of choice for industries and businesses worldwide.