Continuous lamination machines for manufacturing Fiber Reinforced Plastic (FRP) sheets are part of the process used in the production of fiberglass-reinforced composites. This continuous lamination process is used to create large, flat sheets of FRP material that can be further processed into various products. Here's an overview of the continuous lamination process and the key components of a typical FRP sheet machine:

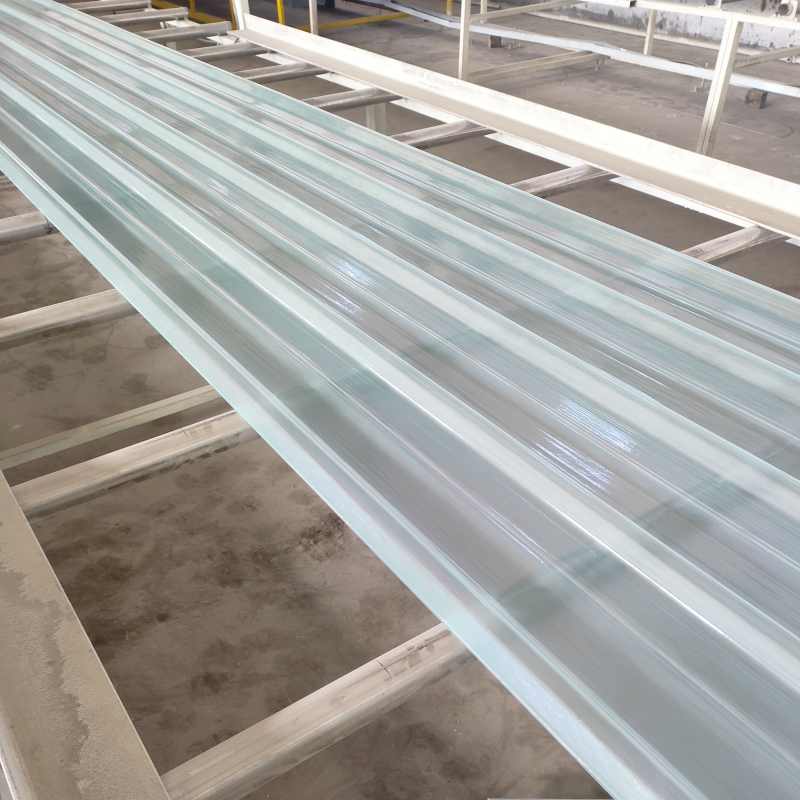

Continuous Lamination Process:Continuous lamination is a method for producing long rolls or sheets of FRP composites. The process involves feeding continuous strands of glass fibers through a resin bath, where they are coated with a thermosetting resin. The resin-coated fibers then pass through a series of rollers and a curing oven to set the resin, creating a solid composite sheet. The resulting FRP sheet can have various applications, including roofing, cladding, and structural components.

Components of a Continuous Lamination FRP Sheet Machine:

Fiber Chopping System:

Continuous lamination begins with the feeding of glass fibers into the machine. In some cases, these fibers are chopped into specific lengths using a fiber chopping system.

Resin Bath:

The chopped or continuous strands of glass fibers pass through a resin bath where they are thoroughly coated with a thermosetting resin. The resin provides the matrix that binds the fibers together.

Laminating Section:

The resin-coated fibers move through a laminating section, where they are arranged into a flat, uniform layer. This section often includes rollers or other devices to ensure proper fiber alignment and resin distribution.

Curing Oven:

Following lamination, the sheets pass through a curing oven. The heat in the oven triggers the curing process, solidifying the resin and creating a durable composite material.

Cooling Section:

After curing, the sheets may pass through a cooling section to bring them to a temperature suitable for further processing or cutting.

Cutting System:

The continuous sheet is then cut into desired lengths or rolls, depending on the intended application.

Winding or Coiling System:

The final FRP sheets are often wound onto rolls for ease of transport and storage. A winding or coiling system facilitates the creation of large rolls of finished FRP sheets.

Quality Control and Monitoring:

Throughout the process, quality control measures are implemented to ensure that the finished FRP sheets meet the desired specifications. This may involve monitoring resin content, fiber alignment, and other parameters.