In industries and sectors where exposure to chemicals, moisture, or adverse environmental conditions is common, it is vital to have materials that offer high resistance and durability. Fiberglass anti-corrosive sheets have become one of the most efficient solutions for protecting installations in these challenging environments. In this article, we'll explore the features, advantages, and applications of these sheets, which are increasingly popular in industrial and agricultural construction.

What Are Fiberglass Anti-Corrosive Sheets?

Fiberglass anti-corrosive sheets are manufactured from high-strength resins and glass fibers. This material combines the lightweight and flexibility of fiberglass with the durability and chemical resistance of resins, making it an excellent choice for installations that are continually exposed to corrosive substances and extreme weather conditions.

Key Characteristics

Corrosion Resistance: Fiberglass sheets are designed to resist the effects of aggressive chemicals, such as acids, alkalis, and solvents. This makes them ideal for chemical plants, processing factories, and agricultural environments where fertilizers and chemicals are used.

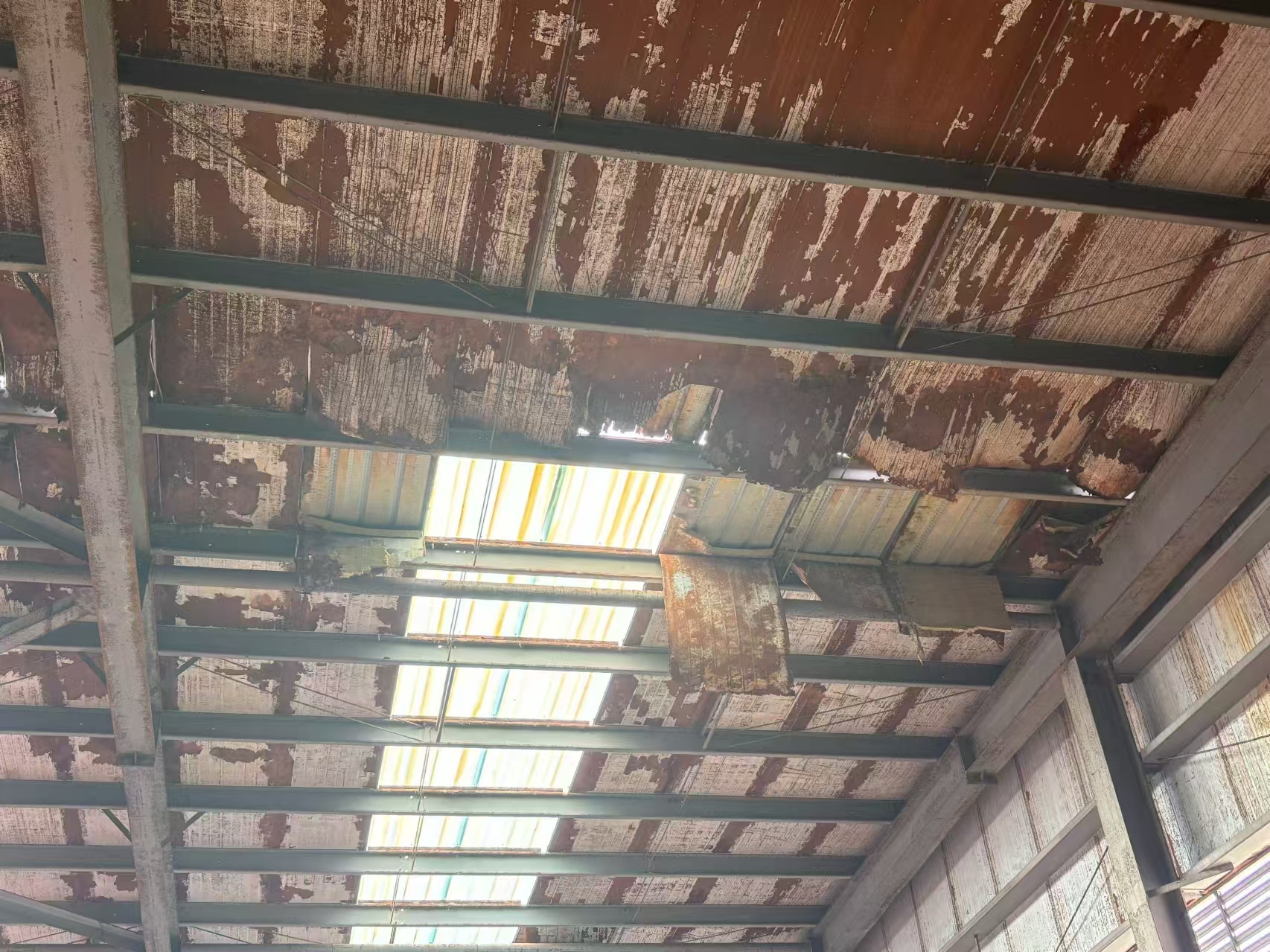

Durability in Harsh Conditions: Unlike other materials like metal, which can rust or corrode over time, fiberglass sheets maintain their structural integrity even when exposed to constant moisture and corrosive agents.

Lightweight and Easy to Install: Being a lightweight material, fiberglass sheets are easy to handle and install. This results in time and cost savings without compromising on strength.

Low Maintenance: Due to their natural resistance to corrosive elements, fiberglass sheets require minimal maintenance, reducing long-term costs.

Versatility: They are available in a variety of thicknesses, sizes, and finishes, allowing them to be tailored to specific applications and needs.

Main Applications

Fiberglass anti-corrosive sheets are used in a wide range of industries due to their unique properties. Some common applications include:

Roofing and Cladding: They are an excellent choice for roofing in factories, warehouses, and farms where a durable material that resists environmental elements is required.

Wall Cladding: In industrial and agricultural settings, walls are often exposed to corrosive substances. Using fiberglass sheets for wall cladding helps protect the structures.

Gutters and Drains: Fiberglass sheets are also used in the production of gutters and drainage systems, as they can withstand the wear and tear caused by water and chemicals flowing through these systems.

Agricultural Installations: In greenhouses and farms, where the use of fertilizers and pesticides can damage other materials, fiberglass anti-corrosive sheets offer a durable, resistant solution.

Advantages in Industrial and Agricultural Construction

The primary advantage of fiberglass anti-corrosive sheets is their ability to withstand harsh environments where other materials fail. In industrial or agricultural construction, corrosion is a major enemy of structural durability. By investing in a strong material like fiberglass, you can ensure the longevity of installations, reduce the risk of damage, and minimize the need for costly repairs.

Their adaptability to various shapes and sizes also makes them ideal for customized projects, such as roofs, cladding, or drainage systems. This provides architects and builders with more flexibility when designing and constructing efficient, durable solutions.

Conclusion

Fiberglass anti-corrosive sheets are an efficient solution for industrial and agricultural environments where exposure to corrosive substances is frequent. Their resistance, durability, and low maintenance make them a smart investment for those looking to protect their installations and extend their lifespan. By choosing fiberglass sheets, you are opting for durability and efficiency, ensuring that your infrastructure remains in optimal condition, even under the most challenging circumstances.