Introduction:Fiberglass-reinforced plastic (FRP) panels have revolutionized industries with their versatility and resilience. At the heart of their durability lies a vital component – the gel coat. This outer layer, often overlooked, plays a pivotal role in safeguarding FRP anticorrosive panels against the elements, ensuring both longevity and aesthetic appeal.

Understanding Gel Coat: A Protective Shield:Gel coat, a specialized resin blend, acts as a protective shield for FRP panels. Comprising polyester or epoxy resin, pigments, and UV-resistant additives, it serves as a frontline defender against corrosive forces, UV rays, and environmental wear.

Functions Unveiled:

Corrosion Resistance:

Guardian Against Corrosive Agents: Gel coat forms an impenetrable barrier, shielding the underlying fiberglass and resin matrix from corrosive substances. It's the frontline defense against chemicals and moisture, preserving the panel's structural integrity.

UV Protection:

Preserving Color and Finish: The additive-rich gel coat wards off the degrading effects of UV radiation. By safeguarding against sunlight, it preserves the color, surface finish, and overall appearance of FRP panels exposed to outdoor elements.

Enhanced Aesthetics:

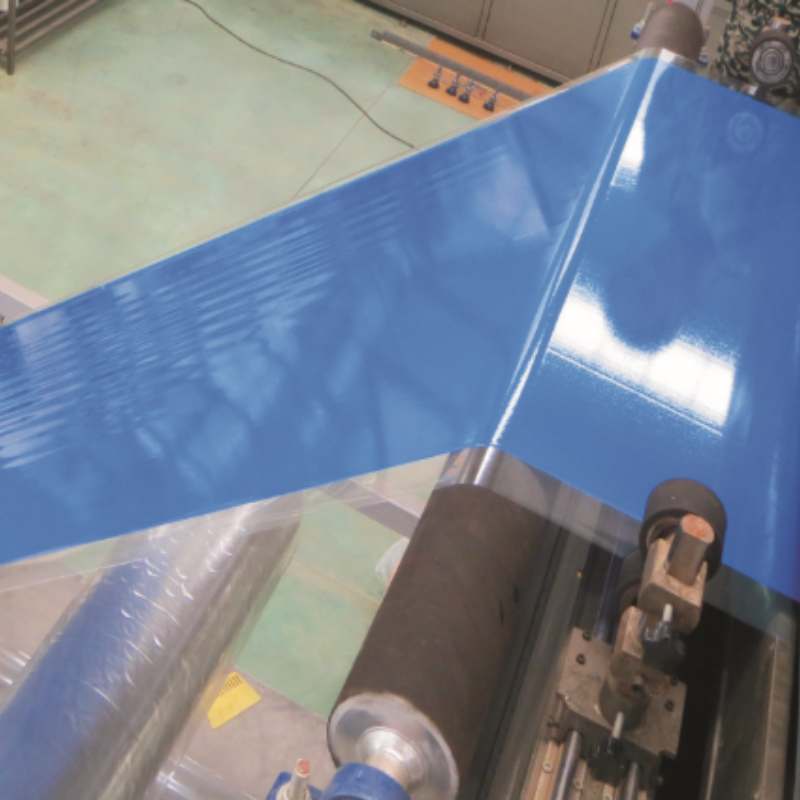

Beauty in Protection: Beyond protection, gel coat contributes to the visual appeal of FRP panels. The smooth, glossy surface finish and customizable pigments ensure a consistent and attractive appearance, making FRP panels stand out.

Impact Resistance:

Defender Against Mechanical Stresses: Gel coat adds an extra layer of toughness, making FRP panels more resistant to impacts and abrasions. This is crucial in applications where panels may encounter mechanical stresses.

Weathering Resistance:

Facing the Elements: Gel coat provides robust weathering resistance, shielding FRP panels from the effects of rain, wind, and temperature fluctuations. This is particularly valuable in applications exposed to diverse weather conditions.

Ease of Cleaning:

Maintaining Hygiene: The gel coat's smooth and non-porous surface simplifies cleaning. This feature is advantageous in applications where cleanliness and hygiene are paramount, such as in the food industry or healthcare settings.

Durability and Longevity:

Ensuring Longevity: By acting as a protective shield, gel coat significantly contributes to the durability and longevity of FRP panels. It's a key factor in ensuring panels withstand the challenges of their intended environment.

Conclusion: Elevating FRP Panels to Excellence:In the realm of FRP anticorrosive panels, gel coat emerges as an unsung hero, tirelessly preserving the integrity and aesthetics of these versatile materials. As industries continue to rely on FRP panels for their structural and design needs, acknowledging the pivotal role of gel coat is essential. It's not just a layer; it's the guardian that ensures FRP panels stand the test of time, embodying excellence in every application.