The service life of FRP lighting panels is intricately tied to their quality. Distinguishing premium quality in FRP lighting panels involves a keen eye for specific characteristics:

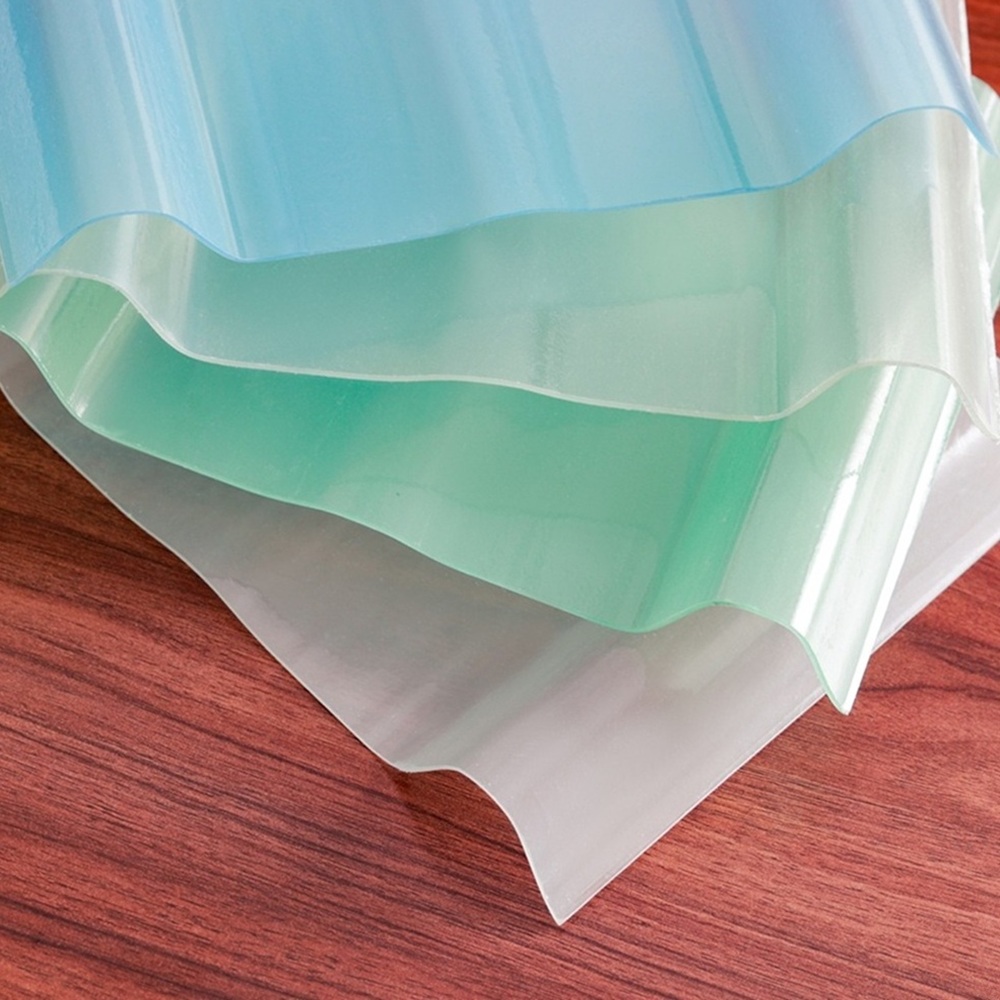

Appearance: High-quality lighting tiles boast a smooth, bright, and wrinkle-free surface with pure and uniform colors. They effectively block sunlight's ultraviolet rays, exhibiting no bubbles, cracks, or impurities that mar their appearance. Uniformly spaced reinforcement ribs enhance strength, preventing breakage or tearing during installation.

Thickness Uniformity: Ensure the lighting board maintains a consistent thickness across all sides to prolong its service life. Inconsistent thickness compromises durability. During installation, avoid tight overlaps to prevent wind, water, and dust infiltration.

Light Transmission: Premium lighting tiles scatter light softly, effectively blocking over 85% of ultraviolet rays. Their exceptional light transmission performance enhances the visual appeal of spaces.

Overlapping and Consistency: Quality lighting tiles seamlessly overlap with color steel plates, displaying uniform cross-section thickness and matching the color steel plate's shape.

Long-Term Performance: After extended use, superior lighting tiles exhibit no discoloration, yellowing, fiber exposure, or cracking, ensuring a prolonged aesthetic appeal.

Toughness: High-quality lighting tiles demonstrate excellent toughness, resisting cracking during roof installation and nailing processes.

Variety and Specification: Premium lighting tiles come in a diverse range of specifications and colors, offering options like general panels, flame-retardant panels, heat-resistant panels, anti-corrosion panels, and flat FRP, catering to different design requirements.

Thermal Expansion Compatibility: The lighting tile's thermal expansion and contraction coefficient closely match that of steel plates, preventing cracking and leaks at nail points.

Inferior quality boards exhibit noticeable flaws:

Abnormal Appearance: Inferior lighting boards often display abnormal colors, such as yellow or green, due to subpar resin and impurities. Wrinkling, bubble cracks, and distorted reinforcement rib spacing result from outdated technology and equipment.

Uneven Thickness: Lower-quality lighting boards may have uneven thickness, compromising their aging resistance and actual thickness. Consistent thickness ensures the board's weight is uniform.

Translucency Issues: Poorly made boards may exhibit translucent turbidity and preserved egg-shaped cracks, stemming from improper raw material ratios and production process issues.

Mismatch and Looseness: Inconsistent shape matching with color steel plates, plate looseness, and shape disparities are signs of inferior quality. These issues may result from worn molds or molds opened too small during manufacturing.

In conclusion, discerning the quality of FRP translucent sheets requires attention to detail and an understanding of key indicators, ensuring the longevity and performance of these essential construction components.