Yo may want to know what´s the differences between polycarbonate sheets and FRP sheet? Let us read this articlue and you may be clear about this question.

Both polycarbonate sheets and fiberglass-reinforced plastic (FRP) sheets are materials commonly used in construction and other applications due to their unique properties. Here's a comparison of polycarbonate sheets and FRP sheets:

Polycarbonate Sheets:

Material Composition:

Polycarbonate sheets are made from a thermoplastic polymer known as polycarbonate. This material is transparent and known for its high impact resistance.

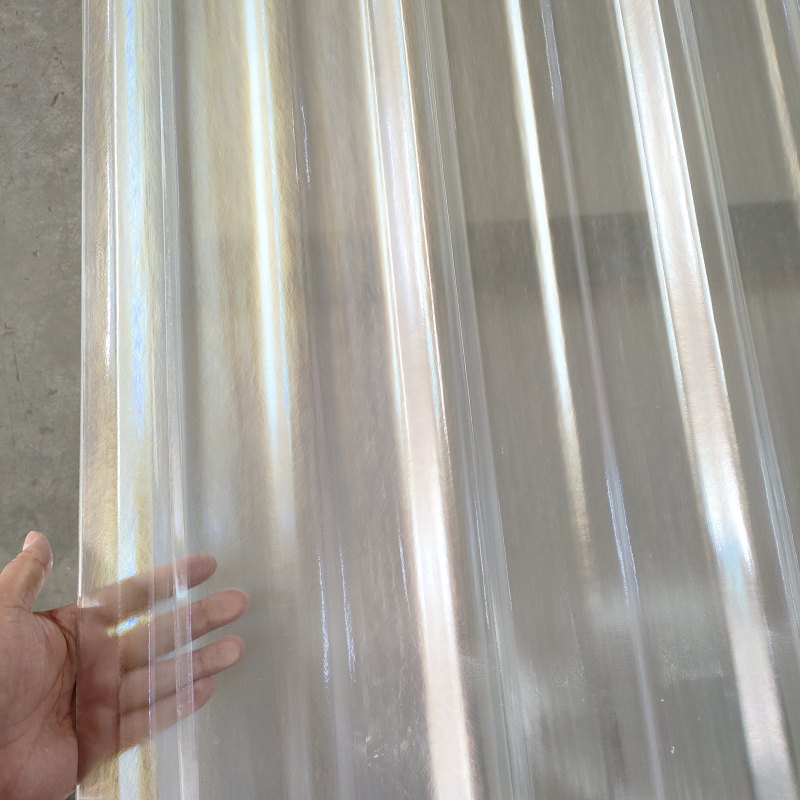

Transparency:

Polycarbonate sheets are transparent, allowing light to pass through. They are often used in applications where clarity and visibility are important.

Impact Resistance:

Polycarbonate is known for its exceptional impact resistance. It is virtually unbreakable and can withstand heavy impacts without shattering.

Temperature Resistance:

Polycarbonate sheets have good temperature resistance, making them suitable for a range of climates. They can handle both high and low temperatures.

UV Resistance:

Many polycarbonate sheets are coated with UV-resistant layers to protect against the harmful effects of ultraviolet (UV) radiation.

Weight:

Polycarbonate sheets are generally lightweight compared to glass, making them easier to handle and install.

Applications:

Common applications include skylights, greenhouse panels, safety glazing, and architectural glazing where transparency and impact resistance are important.

FRP Sheets:

Material Composition:

FRP sheets are made by impregnating fiberglass with a polymer resin, typically polyester or epoxy. The result is a strong and durable composite material.

Strength and Rigidity:

FRP sheets are known for their high strength-to-weight ratio. They are rigid and provide structural strength, making them suitable for various applications.

Corrosion Resistance:

One of the key advantages of FRP sheets is their excellent resistance to corrosion. They are often used in environments where traditional materials may corrode, such as chemical plants and marine applications.

Temperature Resistance:

FRP sheets have good temperature resistance, making them suitable for both high and low-temperature applications.

Customization:

FRP sheets can be customized in terms of thickness, color, and finish, allowing for versatility in design and application.

Applications:

Common applications include industrial panels, roofing materials, wall panels, chemical storage tanks, and other structures requiring high strength and resistance to corrosion.

Considerations for Choosing Between the Two:

Transparency vs. Structural Strength:

Choose polycarbonate sheets when transparency and impact resistance are primary concerns. Choose FRP sheets when structural strength and corrosion resistance are crucial.

Application Requirements:

Consider the specific requirements of your application, such as the need for transparency, resistance to impact, or resistance to corrosive environments.

Weight Considerations:

If weight is a significant factor, polycarbonate sheets are generally lighter. If structural strength and durability are more critical, FRP sheets may be preferred.

Both materials have their strengths, and the choice depends on the specific needs of the project or application. It's essential to evaluate factors such as transparency, impact resistance, structural strength, and resistance to environmental conditions when making a decision.